Liner Rewinder Machine

Liner Rewinder Machine

Standard Features

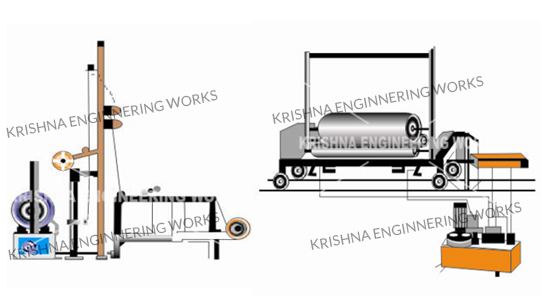

Liner Rewinder Machine is used for any winding & unwinding application for guiding the web to reduce the wastages of the material & to get high production output with minimum man power. We are a leading manufacturer, exporter and supplier of Liner Rewinder Machine from last 25 years, India. Liner Rewinder Machine with heavy duty and high quality equipment. Completely fabricated from Heavy Duty Chanel Angle structure of Rewinder Stand and Let-Off Stand Complete with pneumatic break and Safety Chucks.

- Let off unit.

- Inspection table with pressure roll device.

- Web centering device.

- Two roll surface polling machine with pneumatic pressing device.

Technical Specification

- Completely fabricated from Heavy Duty Chanel Angle structure of Rewinder Stand and Let-Off Stand

- Complete with pneumatic break and Safety Chucks (Locking Assembly) on Let-Off Station

- Inspection Table covered with S.S. Sheet structure-Guider Roller and Light System for Inspection Fabrics

- Platform, Hydraulic Web Aligner (Power Pack) Unit complete with Hydraulic Cylinder, Air Sensor, Adjuster, Square Pipe, Air & Oil Pipe

- Banana Roller to remove the wrinkle

- Rewinder Unit completely manufactured from Heavy Duty Channel Angle and Angle with Pneumatic Cylinder for lifting the Drum Roller

- Necessary Guide Rollers

- 10 HP AC Electric Motor with Synchronized reduction Gear Box

- Electrical Control Panel Drive with Chain Wheel

- Pressure Rubber Roller

- Pneumatic Panel Board for Control of Pneumatic System

- Necessary Safety Covers

Video

Quick Inquiry

[si-contact-form form=’1′]

Our Poducts

- 18Flexible Packaging & Converting Machinery

-

- Rotogravure Printing Machine

- Flexo Printing Machine

- Lamination Machine

- Coating Machine

- Slitter Rewinder Machine

- Inspection Rewinding Machine

- Doctoring Rewinding Machine

- BOPP Slitter Rewinder

- Rotogravure Online Lamination

- Rotogravure Flexo on Extruder

- Core Cutter Machine

- BOPP Slicer Machine

- BOPP Cutting Machine

- Rewinder Unwinder

- Roll Wrapping Machine

- Winding Rewinding Machine

- Web Guiding System

- Trim Rewinder

- 40Tyre-Cord & Technical Textiles Machinery

-

- Liner Rewinder Machine

- Fabric Re Rolling Machine

- High Efficiency Inspection Machine Batching Machine

- Let – Off Stand

- 18Equipments Tyre Cord Dipping Plant

-

- Two Stage Let Off Station

- Automatic Tension Control

- Curved Bar Expander

- Feed Roll System

- Let Off Accumulator

- Center Guiding System

- Fabric Dipping Tank

- Stretch Heat Zone

- Web Master Centering Device

- Pull Roll

- Hot Stretch

- Intermediate Guiding

- Cooling Roll System

- Automatic Centering System

- Wind Up Accumulator

- Automatic Web Guiding Systems

- Trio Canter

- Two Stage Winder

- 11Equipments Calendering Plant

- Liner Drying Machine

- Automatic Festoon Accumulator

- Material Handling System

- Automatic Guiding System

- Cooling Heating Drums

- Core Cutting Machine

- Hydro Pneumo Web Aligner System

- 3Paper Industries Machinery

- 17Textile Processing Machinery

-

- Stenter Machine

- Jigger Machine

- Bowl Mangle Drying Range

- Float Dryer

- Relax Dryer

- Feeder Machine Fabric Infeed Device

- Cloth Guider

- Folding Machine

- Cloth Inspection Machine

- Spares Textile Processing Machinery

- Trolly Material Handling System

- Hot Air Stenter Machine

- Open Batching Stenter Machine

- Super Jumbo Jigger

- Semi Automatic Maxi Close Type Jumbo Jigger Machine

- Semi Jigger

- Spares Stenter

- 13Equipment Machinery