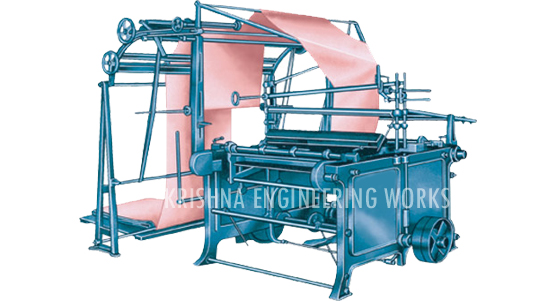

Folding Machine

Folding Machine

Standard Features

Standard Features of Folding Machine, We have been manufacturing, exporting, and supplying high quality and heavy duty Folding Machine from India. Also, we deal on custom requirement in manufacturing Folding Machine per client’s requirement form national and international clients from last 25 years.

- Easy installation and operation.Most powerful model in pneumatic Cloth Guiders.

- Easily mounted on adjustable type support.

- Can be used in vertical, horizontal direction.

- Suitable or use in dry / wet fabrics.

- Different material of rollers are provided for special application.

- Super sensitive web control even without base plates.

- Suitable for higher speed and broader fabric width.

- Safely rods are provided render to avoid accident & to prevent damage to rollers

- Pressure regulating valve with filter & Pressure indicating gauge is provided to adjust the nipping pressure between the rolls for various thickness & tensions.

- Best performance for Woven, Knitted, Towel fabrics, Jute, Tyre cord, Foils.

Technical Specification

Video

Quick Inquiry

[si-contact-form form=’1′]